Eddy Current Magnetic Separators

Eddy Current Magnetic Separators

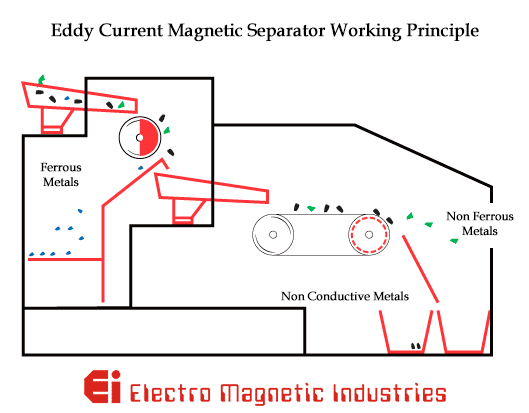

- Eddy Current Separator is designed on the basic theory that introductive current generates whilst conductor is the high frequency alternating magnetic field

- When Eddy Current Separator works, high-frequency alternating magnetic field generates on the surface of the magnetic rotor.

- When non-ferrous metal enter the high-frequency alternating magnetic field, eddy current occurs inside the non-ferrous metal.

- The direction of the magnetic field by eddy current is counter to that of the magnetic field by the high- frequency alternating magnetic field, which leads to rejecting force.

- The rejecting force wills forward-throw non-ferrous metals off the high-frequency alternating magnetic field, so

non-ferrous metals can be recycled effectively.

Application

- Eddy Current Separator is most suitable for re cl ng Copper Aluminum and other non-ferrous metals from industrial rubbish and MSW (Municipal Solid Waste). Nowadays, it’s vastly used in the recycling industries of rubbish, automobiles, electronics, and the material processing of non-ferrous metals etc.

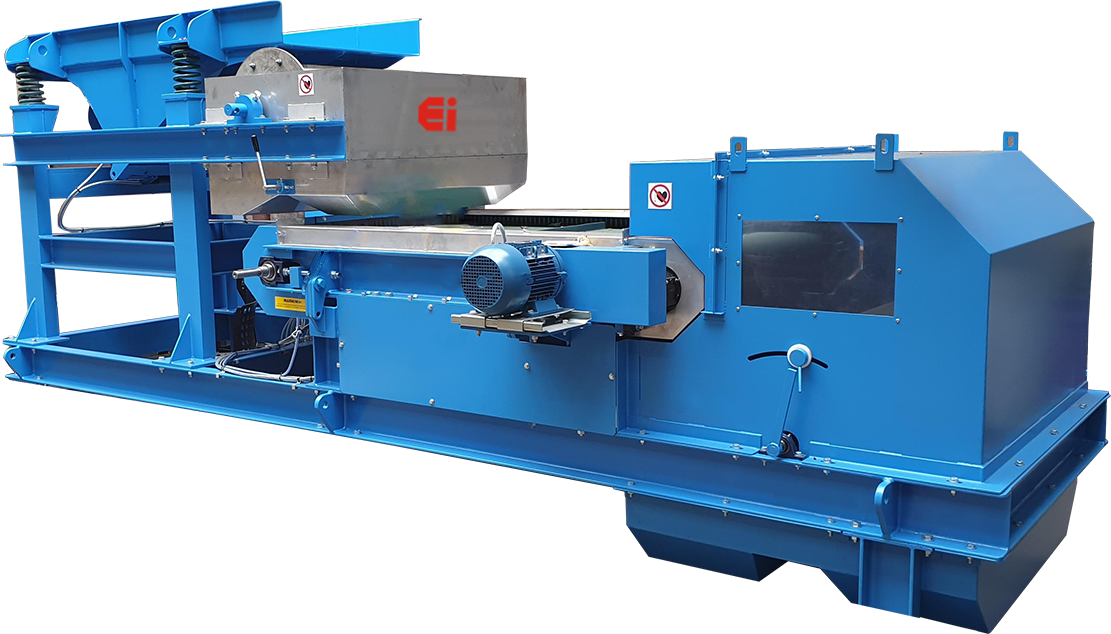

- Eddy Current Separator has better recycling on many kinds of non-ferrous metals. The compact and durable structure strongly suits the coarse working conditions. Strong magnetic field and Variable frequency make Eddy Current Separator a must-have machining in recycling industries.

An eddy current separator is a device used to separate non-ferrous metals like aluminum and copper from non-metallic materials such as plastics, glass, and rubber. Here's how it generally works:

- Principle of Operation: When a conductor (metal) passes through a magnetic field, it induces eddy currents within the conductor due to electromagnetic induction.

- Setup: The separator typically consists of a conveyor belt moving at a consistent speed. Non-ferrous metals and non-metallic materials are fed onto this conveyor belt.

- Eddy Current Effect: The eddy currents generated in the non-ferrous metals create their own magnetic field, which opposes the original magnetic field. This interaction causes repulsion between the metal and the magnetic field.

- Separation: As a result of this repulsion, the non-ferrous metals are ejected from the conveyor belt and diverted into a separate chute or collection area. Meanwhile, the non-metallic materials continue along the conveyor belt.

- Adjustability: The strength and frequency of the magnetic field can often be adjusted to optimize the separation process for different types of materials.

- Applications: Eddy current separators are commonly used in recycling facilities to recover valuable non-ferrous metals from mixed waste streams. They are also used in industries such as mining, where they can separate valuable metals from ore, and in electronic scrap recycling.

Overall, eddy current separators are efficient and effective tools for sorting non-ferrous metals from non-metallic materials based on their differing magnetic properties induced by electromagnetic fields.

Our Eddy Current Separator is used for:

- Eddy Current Separator is used for Aluminium Scrap Recycling

- Eddy Current Separator is used for Rubber Scrap Recycling

- Eddy Current Separator is used for E-waste Recycling

- Eddy Current Separator is used for MSW (Municipal Solid Waste)

- Eddy Current Separator is used for Glass Collect Recycling

- Eddy Current Separator is used for Aluminium Scrap Recycling

- Eddy Current Separator is used for Pet Flakes Recycling

- Eddy Current Separator is used for Wire Scrap Recycling

- Eddy Current Separator is used for Plastic Waste Recycling

- Eddy Current Separator is used for PVC Scrap Recycling

- Eddy Current Separator is used for Zorba